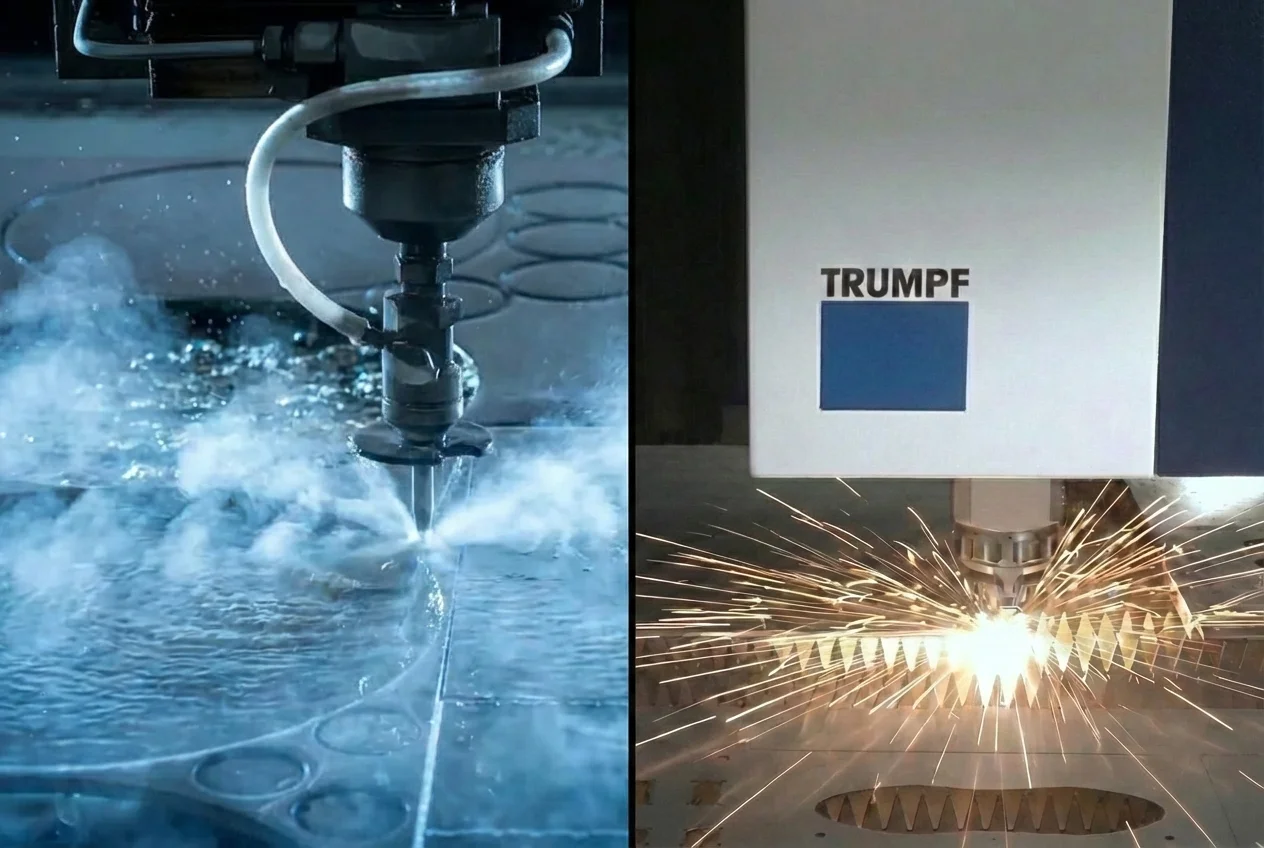

Is Laser Cutting Cheaper Than Waterjet?

Choosing between laser cutting and waterjet? It's a question that comes up constantly, and picking wrong can cost you real money.

Here's the short answer: for most sheet metal work, laser cutting is cheaper. Often by a lot.

Waterjet has its place, but if your part can be laser cut, it almost certainly should be. Let's dig into why.

The Quick Answer

If your part is made from standard sheet metal (steel, aluminum, stainless) under 20mm thick, laser cutting is typically 30-60% cheaper than waterjet. It's faster, more precise, and the operating costs are lower.

Waterjet makes sense when you're cutting very thick material, organic materials like wood or rubber, or exotic materials that don't laser well. Outside of those cases, laser wins on cost.

Why Laser Cutting Is Usually Cheaper

Laser cutting has several cost advantages:

- It's fast. Modern fiber lasers cut thin sheet metal at 70-120+ inches per minute. Waterjet is significantly slower.

- Lower operating costs. Electricity and assist gas are cheap. Waterjet burns through abrasive constantly, and that stuff isn't free.

- Better precision. Laser kerf is tighter (typically 0.1-0.3mm vs 0.5-1.0mm for waterjet), meaning less material waste and better tolerances.

- Faster setup. Load the sheet, run the program. Waterjet requires more setup and often slower pierce times.

- Cleaner edges. Laser-cut edges on sheet metal are often ready to use. Waterjet edges can be rougher and may need secondary finishing.

Why Waterjet Costs More

Waterjet cutting is inherently more expensive because:

- Abrasive consumption. Garnet abrasive is the main consumable, and you go through a lot of it. This alone adds significant cost per part.

- Slower cutting speeds. Waterjet just can't match laser speeds on thin material. Slower = more machine time = higher cost.

- More wear items. Nozzles, mixing tubes, and orifices wear out and need regular replacement.

- Higher maintenance. High-pressure pumps (60,000+ PSI) require more upkeep than laser systems.

When Laser Cutting Saves You Money

Laser cutting is the clear winner when you're making:

- Sheet metal parts under 20mm thick

- Parts from steel, aluminum, stainless, or brass

- High-volume production runs

- Parts requiring tight tolerances (±0.1mm achievable)

- Anything where edge quality matters

- Parts with lots of small holes or fine details

Real numbers: A batch of steel brackets might cost $8-15 each with laser cutting. The same parts on waterjet? $20-40 each. That adds up fast.

When Waterjet Makes Sense

Waterjet earns its keep in specific situations:

- Very thick material (25mm+). Lasers struggle with thick plate. Waterjet handles it without breaking a sweat.

- Organic materials. Wood, rubber, foam, leather, cork - these can't be laser cut without burning or melting. Waterjet cuts them clean.

- Heat-sensitive materials. When you absolutely cannot have any heat-affected zone, waterjet's cold cutting process is the answer.

- Reflective materials. Some materials like copper and certain aluminum alloys can be tricky for lasers. Waterjet doesn't care.

- Glass, stone, and tile. Laser can't touch these. Waterjet cuts them easily.

- Composites and laminates. Carbon fiber, fiberglass, and layered materials often cut better with waterjet.

Some Real Examples

Let's compare typical scenarios:

Steel Brackets (3mm thick, qty 50)

- Laser cutting: $8-12/part

- Waterjet cutting: $22-35/part

Laser wins by 2-3x. This is exactly what lasers do best.

Aluminum Panels (6mm thick, qty 20)

- Laser cutting: $15-25/part

- Waterjet cutting: $35-55/part

Laser still wins by about 2x. Well within laser's sweet spot.

Thick Steel Plate (30mm thick)

- Laser cutting: Struggles or can't do it

- Waterjet cutting: $60-100/part

Waterjet wins by necessity. This is waterjet territory.

Rubber Gaskets (5mm thick)

- Laser cutting: Burns/melts the material

- Waterjet cutting: $15-30/part

Waterjet wins by default. Can't laser cut rubber without ruining it.

Carbon Fiber Panel (3mm thick)

- Laser cutting: Creates toxic fumes, damages material

- Waterjet cutting: $40-70/part

Waterjet wins. Composites and lasers don't mix well.

The Speed Difference Is Real

To put some numbers on it, here's roughly how cutting speeds compare on 6mm mild steel:

- Fiber laser: 80-100+ inches per minute

- Waterjet: 8-15 inches per minute

That's a 5-10x difference in cutting speed. Time is money, and laser cutting just moves faster on sheet metal.

Tips for Keeping Costs Down

For Laser Cutting

- Use standard sheet sizes to avoid material premiums

- Nest parts efficiently to maximize material usage

- Minimize small holes - each pierce adds time

- Order in batches to spread setup costs

For Waterjet Cutting

- Accept standard tolerances unless you need tighter (±0.005" is typical)

- Use thicker material efficiently - waterjet's advantage grows with thickness

- Minimize pierce points - each pierce takes time

- Consider edge quality requirements - faster cuts = rougher edges

Bottom Line

For standard sheet metal work, laser cutting is almost always the cheaper choice. It's faster, more precise, and the operating costs are lower. If your material can be laser cut, it probably should be.

Waterjet is the right call when you're working with very thick material, organics, composites, or anything that can't handle heat. In those cases, the extra cost is worth it because laser isn't an option.

Pick the wrong process and you might pay 30-50% more than necessary. Pick the right one and you'll get great parts at a fair price.

See What Your Parts Would Cost

Want real pricing for your specific parts? Upload your files to Fabworks and get a quote in seconds. Our system will analyze your geometry and give you actual laser cutting prices.

Not sure which process fits your project? We're happy to discuss options. Upload your files and find out.

Is Laser Cutting Cheaper Than CNC Machining?

A practical cost comparison between laser cutting and CNC machining to help you pick the right manufacturing method without blowing your budget.

Using Fabworks for FIRST Robotics (FRC/FTC)

How FIRST teams can leverage on-demand laser cutting and bending to build faster, lighter, and more reliable robots—without slowing down shop time.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.