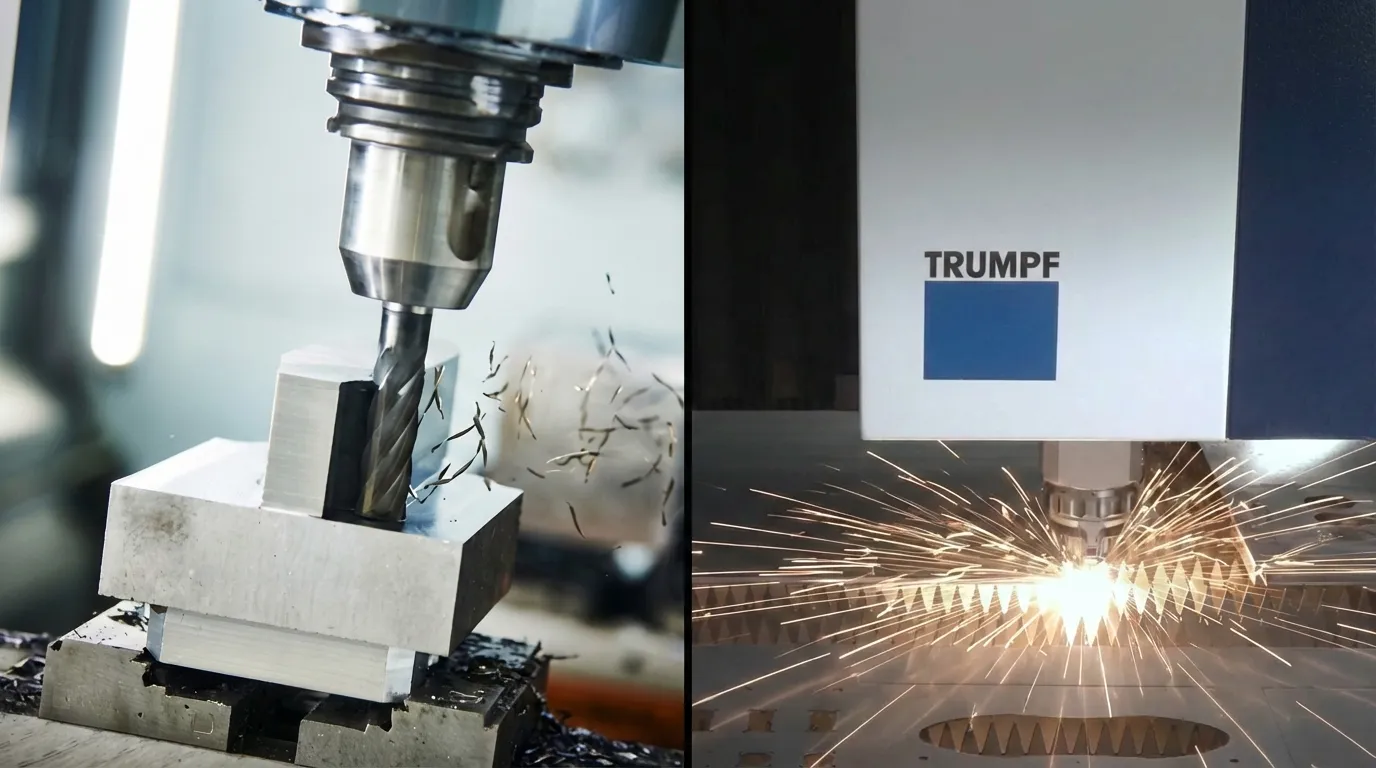

Is Laser Cutting Cheaper Than CNC Machining?

If you're trying to get parts made, you've probably wondered whether laser cutting or CNC machining is the better deal. It's a fair question, and one we hear all the time. The honest answer? It depends on what you're making.

But here's the quick version: for most sheet metal parts, laser cutting wins on cost. Often by a lot.

Let's dig into why that is, and when CNC machining actually makes more sense for your wallet.

The Quick Answer

If your part is flat and made from thin sheet metal (under 10mm), laser cutting is usually 50-80% cheaper than CNC machining. It's faster, wastes less material, and doesn't chew through expensive tooling.

That said, CNC machining pulls ahead when you're working with thick stock, need 3D features, or require super tight tolerances on multiple surfaces. Different tools for different jobs.

Why Laser Cutting Tends to Be Cheaper

A few things work in laser cutting's favor:

- It's fast. We're talking 70-120 inches per minute on thin material. CNC machining can't come close to that speed on flat profiles.

- No tool wear. CNC endmills dull and break. Lasers just... cut. The consumables are minimal.

- Setup is quick. Switching between jobs doesn't require changing out tooling or fixtures. Load the file, load the sheet, go.

- Less waste. Nesting software packs parts tight on the sheet, so you're not paying for material that ends up in the scrap bin.

Why CNC Machining Costs More

CNC machining is inherently more expensive for a few reasons:

- Tool wear: Endmills and inserts dull and break. They need replacing regularly, and that adds up.

- Slower material removal: Cutting away material with a spinning tool just takes longer than vaporizing it with a laser beam.

- More setup: Each job needs fixtures, tool changes, and careful programming.

- Material waste: You're starting with a block and cutting most of it away. That scrap costs money.

When Laser Cutting Saves You Money

Laser cutting is your friend when you're making:

- Sheet metal parts under 10mm thick

- Flat profiles and 2D shapes

- High quantities of similar parts

- Parts with lots of cutouts or fine details

- Anything where you need it fast

To put some numbers on it: a simple steel bracket might cost $5-15 per part with laser cutting. That same bracket machined from billet? $40-100+ easy. The math is pretty clear.

When CNC Machining Makes More Sense

CNC machining earns its keep when you need:

- Thick material (over 20mm)

- 3D features like pockets, steps, or contours

- Tight tolerances on multiple surfaces

- Threads, counterbores, or other machined features

- Parts from engineering plastics or materials that don't laser well

Sometimes there's just no substitute for a good mill.

Some Real Examples

Let's look at a few common scenarios:

A Simple Steel Bracket (3mm thick)

- Laser cutting: $8-12/part

- CNC machining: $45-80/part

Laser wins by 5-7x. Not even close.

An Aluminum Enclosure with Bends (2mm thick)

- Laser + bending: $25-40/part

- CNC from billet: $150-250/part

Laser still wins by 4-6x. Bending adds cost, but it's way cheaper than hogging out all that material.

A Thick Aluminum Plate with Pockets (25mm thick)

- Laser cutting: Can't do it (too thick)

- CNC machining: $80-150/part

CNC wins by default. This is exactly what mills are made for.

A Precision Housing with Tight Tolerances

- Laser cutting: Can't hit the tolerances

- CNC machining: $120-200/part

Again, CNC is the only option when you need that precision across the whole part.

Tips for Keeping Costs Down

Whatever method you go with, here's how to avoid spending more than you need to:

For Laser Cutting

- Stick to standard sheet sizes so you're not paying for oddball material

- Minimize holes and cutouts where you can - each one adds time

- Skip the super intricate details unless they're actually necessary

- Order more at once to spread setup costs across more parts

For CNC Machining

- Design around standard tooling so they don't need special cutters

- Only spec tight tolerances where they matter - everything else can be looser

- Start with stock that's close to your final shape when possible

- Keep it to 3-axis if you can - 5-axis is cool but expensive

Bottom Line

For sheet metal work, laser cutting is almost always the cheaper choice. It's fast, efficient, and doesn't require expensive tooling. If you're making brackets, panels, enclosures, or any kind of flat part, start there.

CNC machining costs more, but it does things lasers can't. Thick material, 3D features, precision fits - that's CNC territory.

Pick the wrong method and you might pay 30-50% more than you need to. Pick the right one and you'll get great parts without the sticker shock.

See What Your Parts Would Cost

Curious what your project would actually run? Upload your files to Fabworks and get a quote in seconds. Our system will analyze your geometry and give you real pricing for laser cutting.

If your parts might need CNC or other processes, we're happy to talk through the options. Upload your files and see for yourself.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.