Guide to Designing Parts for Tapping

Understanding Tapping in Sheet Metal

Tapping is a core technique in sheet metal fabrication. It creates internal threads in laser cut holes, allowing screws and bolts to fit snugly. This ensures mechanical integrity and functionality, making it a go-to method for assembling various products.

Why does tapping matter?

- Mechanical Integrity: Secure attachment of components.

- Design Flexibility: Customizable for different applications.

- Durability: Enhanced longevity of assembled parts.

The process starts with a laser cut hole, which is then threaded to accommodate fasteners, there are many factors to consider during this process.

- Laser Cut Holes: The starting point for threading.

- Thread Size and Pitch: Tailored to material and application.

- Material Type: Different metals require different approaches.

Understanding these basics can set you on the right path. Whether you're working on prototypes or full-scale production, mastering tapping can make all the difference in your project's success.

Best Practices for Designing Tapped Parts

Designing parts for tapping is very. Here’s how to get it right.

Start with clearance holes. These are essential for accommodating the threaded part. Make sure the hole size matches the screw or bolt. For more detailed guidelines on tapping, you can refer to our comprehensive tapping guidelines. Hole size refers to size the hole should be before tapping. Outer diameter is how far out into the material the threads are reaching. If you are configuring your parts for tapping through the Fabworks Tapping Service your hole sizes will be automatically resized for the proper tap.

- Hole Size: Ensure it’s matches the tap chart specified size for the tap size you are using.

- Thread Engagement: Aim for 75-80% of the material thickness worth of engagement for strength.

- Material Thickness: Acceptable thickness will depend on the material and tap size, but generally tapping thinner than 1/8" metal is not recommended for all but light load.

Thread engagement percentage. This impacts how well your screw or bolt holds. Too little engagement, and the connection’s weak.

- Optimal Engagement: 75-80% is ideal.

- Material Consideration: Adjust based on material strength. Softer materials might need more engagement.

Following these tips will help you design parts that hold up, ensuring strong and reliable connections.

Aluminum is soft and needs careful handling to avoid thread stripping. Steel, being harder, can handle tighter tolerances. Plastics might require heat-set inserts for durability.

- Aluminum: Soft, needs careful handling.

- Steel: Hard, can handle tight tolerances.

- Plastics: May need inserts for durability.

By understanding these variables, you can design parts that meet your project’s needs. For more detailed information on the importance of hardware insertion in sheet metal fabrication, check out our Hardware Guidelines. Get the placement right, and you’ll have parts that are both strong and reliable.

Key Takeaways for Designing Tapped Parts

First, understand the tapping process. Tapping creates internal threads in pre-cut holes, allowing screws and bolts to fit snugly. This boosts mechanical integrity and functionality. Accurate hole specifications are important to ensure proper threads. These depend on material type, thread size, and pitch.

- Mechanical Integrity: Ensures secure attachment.

- Thread Size and Pitch: Must match material and application.

- Material Type: Different metals might different taps.

When designing for tapping, focus on clearance holes and thread engagement. Clearance holes should be the proper size, and aim for 75-80% thread engagement for strength.

- Clearance Holes: Sized from a tapping chart for the tap you are using.

- Optimal Engagement: 75-80% for strength.

Material selection is key. Each material—be it aluminum, steel, or plastic—has different properties that affect how you should approach tapping. Aluminum needs careful handling to avoid thread stripping, while steel can handle tighter tolerances.

- Aluminum: Soft, handle carefully.

- Steel: Hard, allows tight tolerances.

- Plastics: May need inserts for durability.

By keeping these guidelines in mind, you’ll design parts that are strong, durable, and ready for assembly.

Comprehensive Guide to Stainless Steel

Stainless steel is a versatile and widely used alloy known for its corrosion resistance and durability.

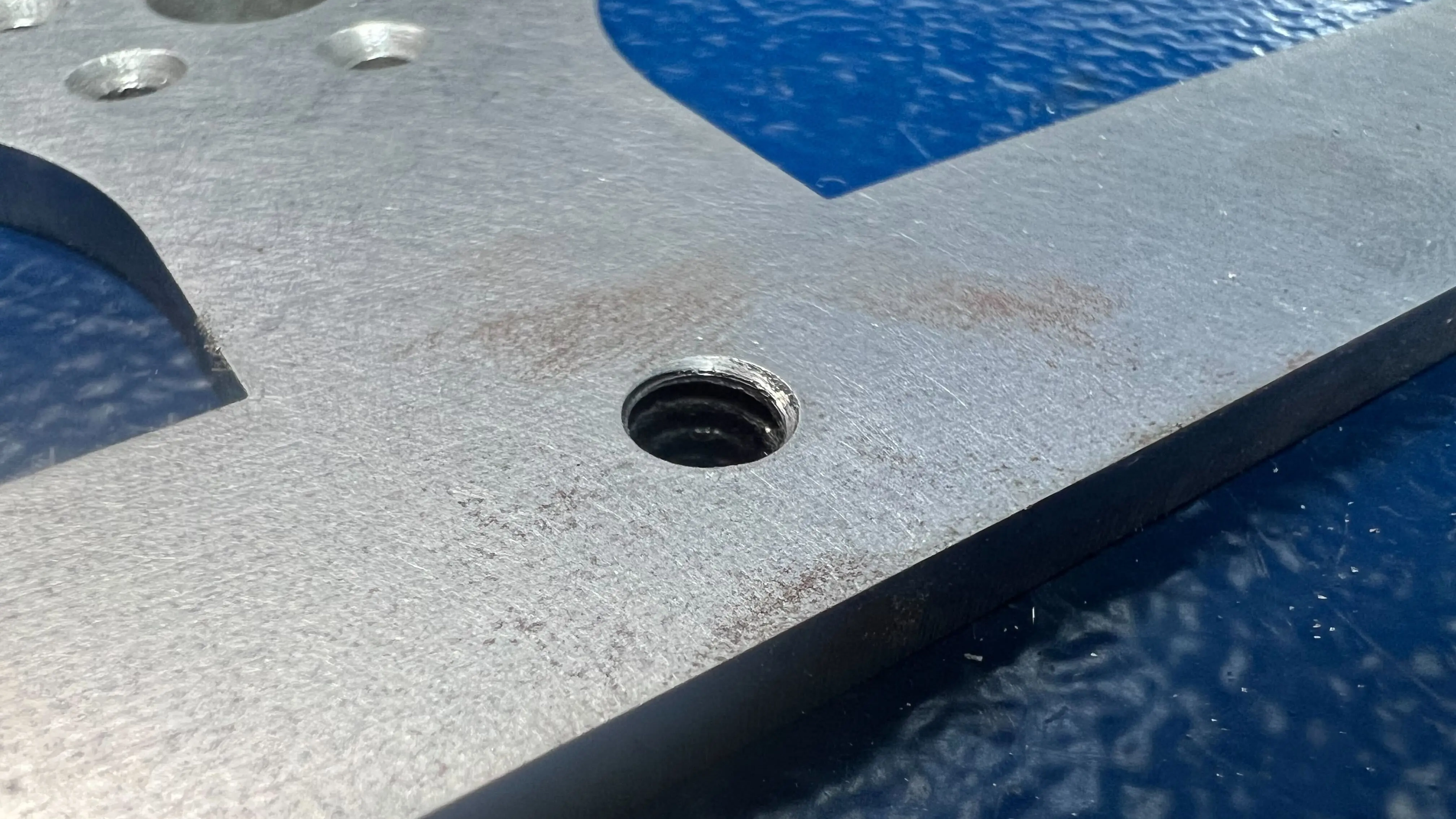

The Benefits of Countersinking in Metal Fabrication

How does countersinking transform metal fabrication? This technique enhances aesthetics, durability, and safety, ensuring flush fastener surfaces in diverse applications like electronics and furniture.

Order Sheet Metal Parts .

Upload your STEP file for an instant laser cutting quote. Quote in seconds, order in minutes, receive parts in days.

or drag and drop

.STEP / .STP up to 25MB

Your file are safe, secure and retain all intellectual rights.